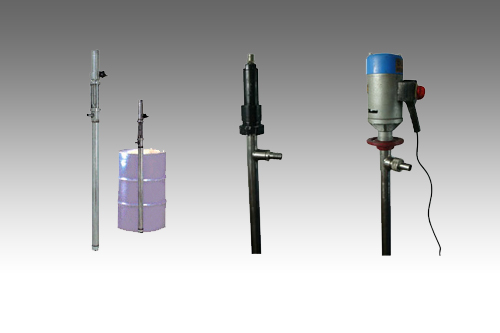

Pneumatic Drum Pump:

Industries make use of many types of pumps for different applications, drum pump is one of them. These pumps are portable and are used to empty barrels, tanks and drums, and are available in different power options. A pneumatic drum pump is one of the types, which is operated by a motor driven by air. This pump converts compressed air energy into mechanical force through linear or rotary motion. Pneumatic drum pumps have applications for transferring liquid from one drum to another drum and is suitable for intermittent or short-term operations. This pump consists of a pump tube and a pneumatic drive motor. For those applications, where explosion-proof pumps are required, and electric or manual drum pumps are not suitable, pneumatic drum pumps are used. These are capable of handling large volumes and have applications in mining, food, beverage and chemical industries.

Oil Skimmer Separator:

In many manufacturing plants,

oily water prevents a plant from functioning and its efficiency is affected by

this. Oil skimming is required when there is waste oil floating on surface of

liquid and it is needed to be removed. An oil skimmer separator is used

for this purpose, and floating oil can be removed with minimal effort. Water is

used in processing plants for cooling of machines, washing of equipment or for

processing. It happens sometimes, that water picks up oil or grease from

machines. If this water is to be reused then it is needed to remove this oil from

the water before it is reused, and for this, oil skimmer separator is used. Few

benefits of oil skimming are that it reduces cost and makes the treatment more

efficient. Removed oil can be valuable, and if an outside contract is given for

this work, it costs much more than using oil skimmer. Use of oil skimmers

prevent foul odours and automatic oil skimmer can be used to do the task

automatically.

Grease Pump:

Grease is a semisolid material

which is used for lubrication of mechanical moving parts of machines. If grease

is to be drawn from a tank or vessel then there is need of a pump to take out

the grease. This pump must be a positive displacement pump, because, a

centrifugal pump will not solve the purpose. Use of grease pump, extends

maintenance period of the facility and reduces the maintenance time. It also

reduces lubrication failure, and maintenance cost along with increasing turnout

rate and operational efficiency.

Comments

Post a Comment